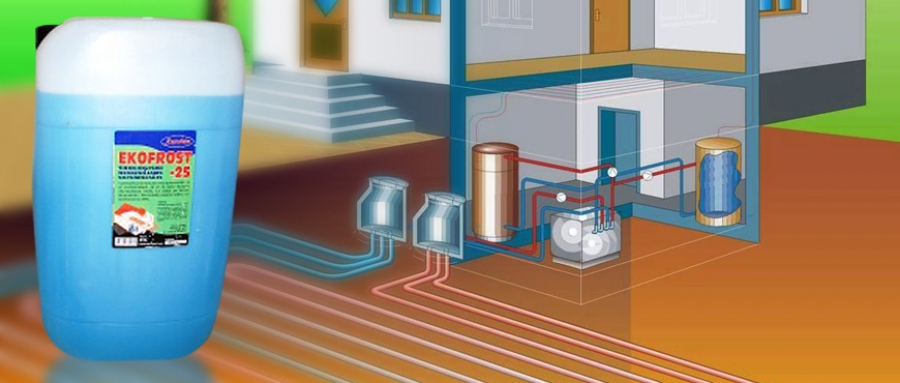

Heat transfer fluid — is the foundation of reliable operation of heating and ventilation systems in industrial facilities, shopping centers, and private homes. The most common types of heat carriers for heating systems are aqueous solutions of glycols and alcohols.

Water has good heat capacity and fluidity, and that’s where its advantages end. Its use causes corrosion of all metal parts of the heating system and leads to calcium deposits. At temperatures below 0°C, water freezes and disables the entire system.

That’s why specially developed low-freezing liquids — heat transfer fluids and refrigerants (solutions of ethylene glycol, propylene glycol, and alcohol with various additives) — are now widely used in heating and ventilation systems.

The heat carrier contains corrosion inhibitors and various other additives. Inhibitors are substances that slow down chemical processes such as metal corrosion, polymerization, and oxidation. Other additives prevent scale formation, swelling and dissolution of rubber seals, foaming, cavitation, etc. They prevent the heat carrier from damaging structural materials and joints within the operating temperature range. Inhibitors make the heat carrier a chemically stable product.

For consumer convenience and ease of transportation, the heat transfer fluid is sold both as a concentrate (95% ethylene glycol) and in a ready-to-use form.

When purchasing a concentrate, the consumer should be aware that "local" water used for dilution may cause a reaction — precipitation. The most problematic aspect is that the inhibitors necessary for the antifreeze to function properly may precipitate. Therefore, specialists recommend purchasing ready-to-use solutions or using demineralized (purified) or distilled water for dilution.

The main disadvantage of ethylene glycol is its toxicity. If this substance comes into contact with skin or enters the human body, it causes chemical poisoning. Its vapors are also harmful. The lethal dose of ethylene glycol for humans is 5 milligrams per 1 kg of body weight. Heat transfer fluids based on ethylene glycol are not used in systems related to food, water supply, or open heating systems (with open expansion tanks), where evaporation is possible.

The optimal heat carrier for any system is a solution based on propylene glycol. Possessing all the necessary properties, it is absolutely non-toxic and can be used in systems with high environmental safety requirements.

AUTOHIM offers customers heat transfer fluids based on ethylene glycol and propylene glycol according to its own original formulations. The company’s heat transfer fluids and refrigerants guarantee low freezing points, reliable protection of the system against corrosion, scale, and many other problems.

The company “AUTOHIM” also produces an eco-friendly heat carrier based on an alcohol mixture, which has increased heat capacity and fluidity, making it ideal for use in outdoor circuits of heat pumps.

The specialists of AUTOHIM provide consulting support — from familiarization with the project and selection of heat transfer fluid characteristics based on client requirements, to delivery to the site.

The warranty period of the heat transfer fluids is designed for 5 to 7 years of continuous operation or 10 heating seasons.

For its clients, AUTOHIM offers periodic analysis of the working heat transfer fluid, which allows determining the condition of the solution and providing recommendations for maintaining its performance characteristics, as well as identifying problems in the heating system in a timely manner.