INSTALLATION

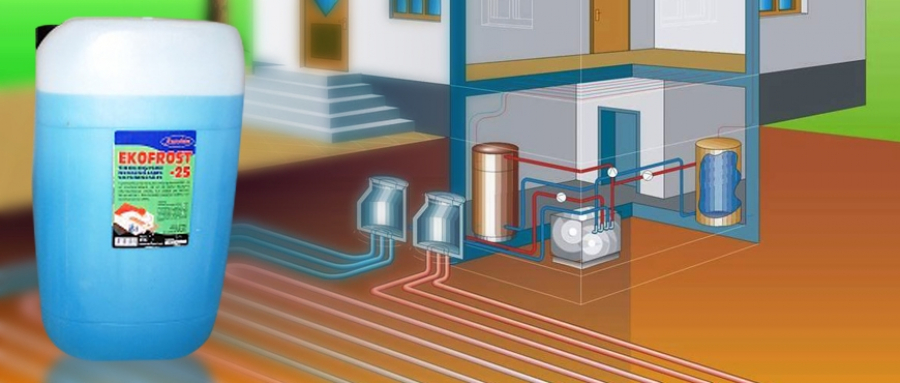

Environmentally safe low-freezing heat carrier designed for the "cold" circuits of heat pumps and other heat exchange units with forced circulation.

Endowed with elevated heat capacity and fluidity.

COMPOSITION

"EKOFROST” heat carrier represents a water-alcohol solution with a multifunctional alloying additive. Its production uses specially purified and "softened" water, which enhances its stability in operation.

USAGE CHARACTERISTICS

"EKOFROST heat carrier" emerges in a scenario ready for application:

"EKOFROST-20" and "EKOFROST-25" with crystallization starting temperatures of -20º and -25º respectively.

By customer order, "EKOFROST - concentrate" is produced, using "EKOFROST-conc". It must be diluted with technical water, distilled water, or specially purified and softened water according to the table shown below:

| Freezing temperature | "EKOFROST-conc content" (%) | Water (%) content |

|---|---|---|

| Minus 40˚C | 56 | 44 |

| Minus 30˚C | 42 | 58 |

| Minus 20˚C | 30 | 70 |

The heat exchange system must be hermetic, so that the alcohol does not evaporate and the heat carrier does not lose its properties. Additionally, it should not be heated above 30-35ºC because the boiling temperature of the heat carrier is 75-80ºC.

"EKOFROST” heat carrier allows operations in ambient temperatures below zero.

The heat exchange system must be hermetic, the alcohol must not evaporate, and the cooling must not lose its properties. Additionally, it is not permissible to heat the cooler temperature above 30-35°C, since the boiling point of the cooler is 75-80°C. The "EKOFROST" cooler allows operations at negative temperatures.

While maintaining operating conditions, the heat carrier is designed for a lifespan of 5 years of continuous operation or 10 heating seasons.

SYSTEM PREPARATION

Reliable and long-term system operation with "EKOFROST heat carrier" requires preliminary work.

Before introducing the heat carrier into the heating or air-conditioning system, it is necessary to perform a hydrotest and check its operation at positive temperatures with water, and at negative temperatures with antifreeze.

If leaks are found, pour in the fluid, solve the problem, and test again.

Before introducing the heat carrier into the old system, it is necessary to previously flush them with fluid for cleaning.

Before introducing the heat carrier into the old system, it is necessary to previously flush them with fluid for cleaning.

STORAGE

Heat carriers should be stored in a place inaccessible to children.

Shelf life - 3 years from the date of production.

PACKAGING

Cans: 10 and 25 liters, Barrels: 210 liters, Containers: 1000 liters